- FIRST-CLASS SUPPORT

- #1 PRICE-QUALITY RATIO

- 35 YEARS OF EXPERIENCE

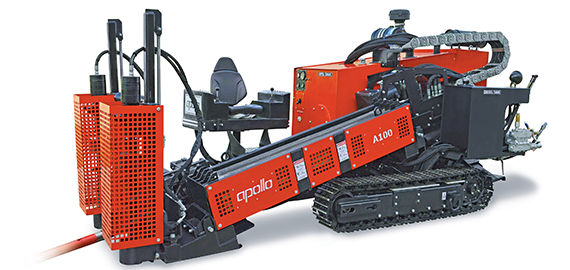

A800 R HDD

A 20-ton drilling rig (push and pull force)

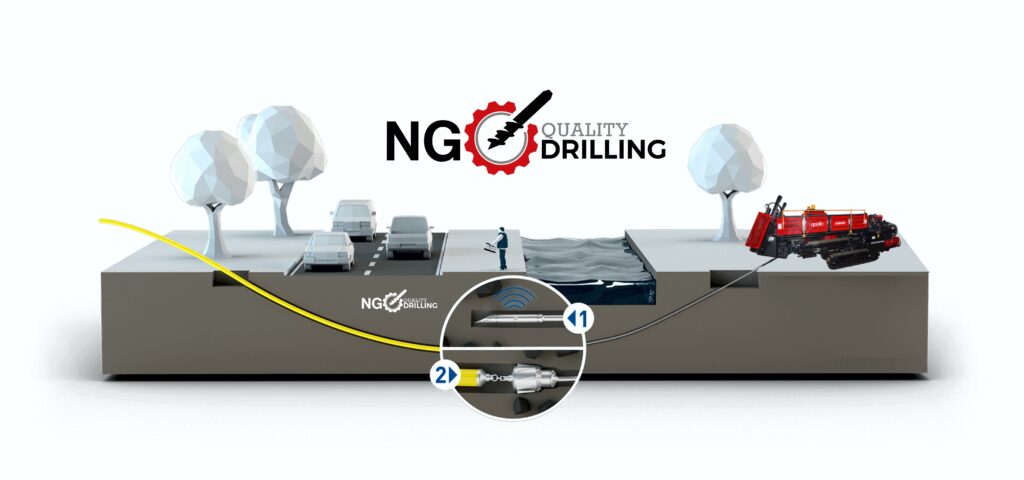

The Apollo A800 R is designed for installing a range of small to medium diameter cables and pipelines and features a rack and pinion system along with a Caterpillar Tier IV engine. Along with the more powerful engine, the pushing and pulling force has increased to 20 tons with a torque of 6,500 Nm. The A800 R is equipped with a comfortable and spacious driver’s cabin; the driver’s seat can be rotated 180 degrees. The A800 R has an automatic rod loading system. Additionally, the A800 R offers three variable drilling speeds for different soil conditions. Extra special features include the automatic drilling function and the half-rotation function (optional). The Apollo drill rod is forged from a single piece.

Reliable, powerful and robust. With these key words we broadly summarize the Apollo drilling machines. No-nonsense machines with the aim of running production. The Apollo machines represent the best price-quality ratio available on the market. Supported by a full team of experts, service technicians and stock of parts, you are assured of the best support.

The Apollo drills are available from 5 tons, meaning there is a suitable model for everyones’s needs.

We would like to refer to our general Apollo brochure.

Click on the machine type for all detailed information.

Martin (HDD Driller) on Apollo Drilling Machines

Read more general questions and answers about Apollo

MEET THE HDD DRILLS FROM APOLLO

WHY CHOOSE APOLLO?

Reliable, powerful and robust. These key words broadly summarize Apollo’s drilling machines. No-nonsense machines with the goal of rotating production. Apollo machines represent the best value for money on the market. Backed by a complete team of experts, service engineers and a stock of spare parts, you are assured of the best support.

Apollo drills are available from 5 tons upwards, meaning there is a suitable model for everyone’s needs.

Please refer to our general Apollo brochure

Click on the machine type for all detailed information.

Of each type of machine sold, all parts and wear parts are sufficiently stocked. If parts are needed, they are brought directly via our own mobile service department or shipped via our logistics partners. NG Quality Drilling works with its own mechanics who communicate in the working language of the on-site personnel. The focus is on Germany, so the work area is of such a size that we can always be on site within 2 to 4 hours to repair faults.

The Apollo drilling machines, parts and wear parts are produced in India; a low-wage country. As a result, the costs for both the machine and the various parts are significantly lower, while, if we also consider that the Apollo has long been an established name within HDD in Asia, the quality is at least comparable to the providers, as we currently know them in Europe.

That math is easy to do:

The machine is manufactured in India. The low wages there result in a much lower cost of manufacturing the machine. In addition, there are no middlemen pushing the price up unnecessarily. NG Quality Drilling communicates and trades directly with the producing party in India. The lines are short, which also ensures that the cost of the machines is kept to a minimum.

The bottom line is that we ship the machine, which can be produced cheaply in India at the same if not higher quality (compared to the existing brands in the EU) directly to Europe, without third party intervention. This allows the price of the Apollo to be a lot lower than that of the machines, as we know them now in Europe.

Apollo is a well-known name in Asia. The manufacturer has been in business since 1967 and is one of the major players in the Asian market. Initially they produced Vertical Drilling machines, 15 years ago they also concentrated on Horizontal Drilling rigs.

The manufacturer boasts a long track record and many satisfied customers. The reliability of the machine is thus beyond question.

The Apollo is similar to the machines now used in the European market. Nevertheless, we spend time on commissioning the machine. Each machine comes with a comprehensive, clearly written manual in its own language. We also take the time to answer all questions about the machine. We do this on site, at the driller’s premises, in person. The German support comes directly from the manufacturer and is therefore well versed in the machine from the start and also knows how to communicate this clearly. In short, every machine comes with on-site training and is given to the people who will operate the machine.

We use the usual warranty of 1 year or 1,000 hours of operation. There is no difference in this with alternative providers. What does distinguish us is our level of support and service. If there are any problems, we are ready to help you 24/7. Because we understand the (financial) consequences if a machine comes to a standstill. We know what is going on in the field and are ready to help you further. Our mobile service department is ready to come to you directly to solve any problems. We work with our own mechanics who are both skilled in the field and communicate in both English and German.